What are the main differences between automatic spray guns and manual spray guns?

Automatic Spray Guns vs. Manual Spray Guns – Key Differences, Benefits, and Applications

Introduction to Spray Gun Types

Spray guns are essential tools in industrial coating and finishing. The two primary categories, automatic spray guns and manual spray guns, serve different needs based on production scale, precision requirements, and operational flexibility. Understanding their differences and typical applications helps businesses choose the right solution for optimal performance and cost efficiency.

Manual Spray Guns – Flexibility for Custom and Small-Scale Operations

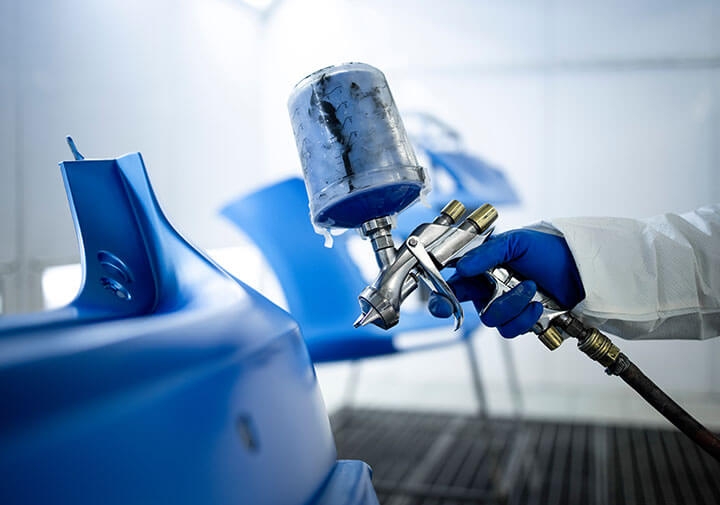

Manual spray guns, also called handheld spray guns, require direct operator control. The user adjusts spray angles, patterns, and distances in real time, offering unmatched versatility and adaptability for smaller or custom projects.

Advantages of Manual Spray Guns

- High Operational Flexibility: Ideal for irregular shapes, touch-ups, and low-volume jobs

- Lower Initial Investment: Equipment cost is significantly lower compared to automated systems

- User-Controlled Precision: Operators can adjust spray parameters on the spot

Limitations of Manual Spray Guns

- Operator Dependency: Coating quality depends on the skill and consistency of the user

- Potential for Inconsistency: Uneven paint layers or thickness variations may occur

- Higher Labor Costs: Prolonged manual operation increases fatigue and operational expenses

Typical Applications of Manual Spray Guns

Manual spray guns are widely used in:

- Furniture finishing for wood coatings and decorative details

- Automotive repair for small-scale painting or retouching

- Custom metal fabrication where flexibility is required

- Construction and building materials for on-site coatings

- Small-scale manufacturing with frequent design changes

Automatic Spray Guns – Efficiency and Consistency for Mass Production

In contrast, automatic paint spray guns, also referred to as automated spray systems or pneumatic spray equipment, are mounted on robotic arms or fixed equipment, operating through pneumatic or electronic control systems for unmanned, consistent spraying.

Advantages of Automatic Spray Guns

- High Production Efficiency: Perfect for high-volume, repetitive coating tasks

- Consistent Quality: Pre-programmed spray parameters ensure uniform finishes

- Reduced Labor Dependency: Minimal operator involvement lowers long-term costs

- Scalable Automation: Integrates easily into automated production lines

Considerations for Automatic Paint Spray Guns

- Higher Initial Costs: Equipment and integration expenses are higher upfront

- Less Flexibility: Best suited for standardized production rather than custom work

Typical Applications of Automatic Spray Guns

Automatic paint spray gun are commonly used in:

- Automotive manufacturing for large-scale vehicle painting

- Appliance production for uniform surface coating

- Metal processing and finishing for industrial components

- Electronics and 3C products requiring precise coating layers

- Furniture and cabinetry manufacturing for mass production lines

- Plastic packaging and cosmetic containers for consistent finishes

Conclusion – Choosing the Right Spray Gun for Your Needs

The choice between automatic spray guns and manual spray guns depends on production scale, cost considerations, and coating precision requirements. The table below summarizes the main differences:

| Feature / Aspect | Manual Spray Guns (Handheld) | Automatic Spray Guns (Automated Systems) |

|---|---|---|

| Operation Method | Operator-controlled trigger, angle, and distance | Pneumatic/Electronic control with preset parameters |

| Flexibility | High, suitable for irregular shapes & touch-ups | Low, best for standardized, repetitive processes |

| Coating Consistency | Dependent on operator skill | High, uniform thickness & finish |

| Production Volume | Small to medium-scale or custom projects | Large-scale, high-volume manufacturing |

| Initial Investment | Low equipment cost | Higher cost for equipment & automation integration |

| Labor Dependency | High, manual operation required | Low, minimal operator involvement |

| Typical Applications | Furniture finishing, automotive repair, custom jobs | Automotive production, appliance painting, metal coating |

| Long-Term Operating Cost | Higher due to labor expenses | Lower due to efficiency and reduced manpower needs |

This comparison helps businesses evaluate which system aligns best with their budget, production capacity, and quality requirements.

High-Quality Automatic Paint Spray Guns from RANOX

For manufacturers seeking reliable and efficient coating equipment, RANOX ENTERPRISE INC. offers a complete line of automatic paint spray guns designed for industrial use. Built in Taiwan with a focus on precision, durability, and performance, RANOX products help businesses enhance production efficiency and maintain superior coating quality.