Which industries see the most efficiency gains from using automatic spray guns?

Automatic spray guns have become a core component of modern automated coating systems. As manufacturers across industries pursue higher productivity, stable quality, and lower operating costs, automatic spray guns are increasingly adopted to replace or supplement manual spraying processes. Their ability to deliver consistent coating results, precise material control, and seamless integration with automated production lines makes them especially valuable in high-volume and quality-sensitive environments.

This article analyzes which industries experience the most significant efficiency gains from automatic spray guns, why these gains occur, and how automated spray systems support broader industrial automation and sustainability goals.

Industries That Benefit Most from Automatic Spray Guns

Automotive Industry

The automotive industry is widely recognized as one of the earliest and most intensive users of automatic spray guns. Automated paint application systems are used for vehicle bodies, frames, and components to achieve uniform film thickness and high-quality surface finishes.

Key efficiency gains include:

- Stable and repeatable coating quality across large production volumes

- Reduced paint overspray and material waste

- Faster cycle times compared to manual spray operations

- Lower labor dependency and improved operator safety

By integrating automatic spray guns with robotic arms and conveyor systems, automotive manufacturers can maintain consistent output while meeting strict appearance and corrosion-resistance standards.

Furniture and Woodworking Industry

Furniture, cabinetry, and wood product manufacturers rely heavily on surface finishing for both aesthetics and durability. Automatic spray guns for wood finishing enable uniform coating over large panels and complex shapes while maintaining consistent color and gloss levels.

Efficiency improvements in this sector include:

- High-speed, large-area coating suitable for mass production

- Reduced rework caused by uneven finishes

- Lower material consumption through controlled spray patterns

- Improved production planning and throughput stability

Automated spray systems are particularly valuable for manufacturers supplying standardized furniture products at scale.

Metal Products and Home Appliance Industry

Metal components and home appliances require protective and decorative coatings to enhance durability, corrosion resistance, and visual appeal. Automatic spray guns allow precise control of coating thickness, helping manufacturers meet functional and regulatory requirements.

Major efficiency gains include:

- Lower defect rates caused by inconsistent manual spraying

- Improved compliance with environmental standards, including VOC reduction

- Reduced material waste and improved cost predictability

- Enhanced repeatability across multiple product models

Automated coating systems are especially effective for appliance housings, metal panels, and industrial enclosures.

Plastics and Electronics Industry

Plastic parts and electronic enclosures often require both cosmetic and functional coatings, such as UV protection, anti-scratch layers, or electromagnetic shielding. Automatic spray guns for plastic and electronics coating provide the flexibility needed to handle diverse product specifications.

Efficiency advantages include:

- Rapid parameter switching for different products

- Precise application of thin, functional coatings

- Compatibility with cleanroom or controlled environments

- Support for high-mix, medium- to high-volume production

This flexibility allows manufacturers to respond quickly to changing product designs without sacrificing coating consistency.

Agriculture and Construction Applications

Beyond traditional manufacturing, automatic spray guns are also used in agriculture and construction for large-area and precision spraying tasks.

In agriculture, automated spray systems help:

- Control pesticide and fertilizer dosage accurately

- Reduce chemical usage and environmental impact

- Improve coverage consistency across crops

- In construction, automatic spray guns are applied to:

- Protective coatings for steel structures

- Adhesives, sealants, and insulation materials

- Large surfaces requiring uniform application

These applications improve operational efficiency while supporting safety and environmental objectives.

Medical, Healthcare, and Public Facilities

Healthcare environments increasingly use automatic spray guns for surface disinfection and protective coatings. Automated spraying ensures consistent disinfectant coverage across large areas, reducing reliance on manual labor.

Efficiency benefits include:

- Faster disinfection of large spaces

- Reduced human exposure to chemicals

- Repeatable and standardized sanitation processes

These systems are commonly used in hospitals, laboratories, and public facilities where hygiene standards are critical.

Why Automatic Spray Guns Deliver Significant Efficiency Gains

- Consistency and Process Control:Automatic spray guns operate based on predefined parameters such as flow rate, spray pattern, and atomization pressure. This eliminates variability caused by manual operation and ensures every coated product meets the same quality standard.

- Higher Productivity and Throughput:Automated spray systems can operate continuously with minimal downtime, making them ideal for mass production environments. Compared to manual spraying, automatic spray guns significantly increase line speed and output stability.

- Material Savings and Cost Optimization:Precise spray control reduces overspray, coating thickness variation, and material waste. Over time, this leads to lower raw material consumption, reduced cleanup costs, and more predictable operating expenses.

- Improved Safety and Environmental Performance:By minimizing direct human involvement, automatic spray guns reduce operator exposure to hazardous substances. When combined with filtration and recovery systems, they also help manufacturers meet environmental regulations and sustainability targets.

- Integration with Automated Production Lines:Automatic spray guns can be easily integrated with robots, conveyors, and smart manufacturing systems. This flexibility allows manufacturers to scale production, adapt to new products, and move toward fully automated factories.

Conclusion

Industries that demand high production efficiency, consistent coating quality, and strict cost control, such as automotive, furniture, metal processing, plastics, electronics, agriculture, construction, and healthcare, experience the greatest efficiency gains from adopting automatic spray guns. These sectors share a common need for repeatability, speed, and process reliability.

By enabling precise control, reducing waste, and supporting automation, automatic spray guns play a critical role in modern industrial production and continue to drive efficiency improvements across a wide range of applications.

Learn More About Automatic Spray Guns

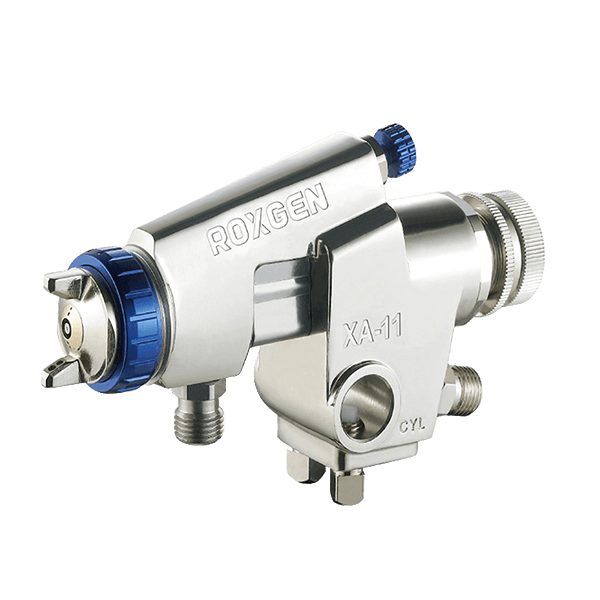

For manufacturers and system integrators evaluating automated coating solutions, understanding different automatic air spray gun designs and specifications is a critical first step.