How does the HVLP technology improve the performance of automatic spray guns?

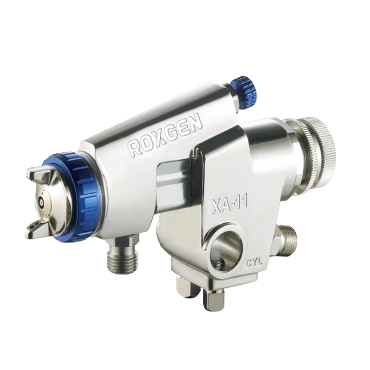

HVLP Automatic Spray Guns Enhance Coating Performance

HVLP automatic spray guns have become essential tools in modern industrial coating processes. By using high-volume, low-pressure technology, these spray guns offer precise and uniform application of paints and coatings while reducing material waste and overspray. Ideal for automotive, furniture, aerospace, and industrial equipment applications, HVLP automatic spray guns provide both efficiency and high-quality finishes. This article explores their benefits, key applications, and why they are a smart investment for manufacturers seeking cost-effective and reliable coating solutions.

What is HVLP Technology in Automatic Spray Guns?

HVLP (High Volume Low Pressure) automatic spray guns utilize a combination of high air volume and low air pressure to deliver coatings more evenly and efficiently. Unlike traditional high-pressure spray systems, HVLP spray guns minimize overspray and bounce-back, offering precise control over the spray pattern while reducing material waste. This makes HVLP paint guns ideal for industries that require both high-quality finishes and cost-effective coating solutions.

Key Benefits of HVLP Automatic Spray Guns

1. Increased Transfer Efficiency and Material Savings

HVLP technology significantly improves transfer efficiency, which is the amount of coating material that successfully adheres to the surface. Standard high-pressure spray guns typically achieve around 40 percent transfer efficiency, whereas HVLP automatic spray systems and HVLP paint guns can reach approximately 49 percent and even up to 61 percent when using optimized spraying techniques. By increasing material utilization, these precision coating tools help manufacturers save on coating costs and reduce environmental impact, limiting harmful chemical emissions.

2. Superior Coating Quality and Surface Finish

With lower spraying pressure, HVLP automatic spray guns apply coatings more gently and uniformly. This reduces common surface defects such as orange peel textures, runs, or uneven gloss. The result is a smooth, consistent finish that meets the high standards of automotive, furniture, and industrial applications where surface aesthetics and precision are critical.

3. Consistency and Automation Efficiency

HVLP automatic spray guns are particularly effective when integrated into automated production lines. Their high transfer efficiency and precise control ensure uniform coatings across large batches while minimizing quality variations caused by manual operation. Continuous and stable operation not only enhances productivity but also reduces labor costs, making automated HVLP paint guns a smart investment for modern manufacturing facilities.

Applications of HVLP Spray Guns

HVLP paint guns are widely used across industries where precise, high-quality coating is required. Typical applications include:

- Automotive Industry: Painting car bodies, automotive parts, and repair work with smooth, defect-free finishes

- Furniture and Woodworking: Applying stains, lacquers, and varnishes evenly on wood surfaces without runs or drips

- Aerospace Components: Coating aircraft parts that require uniform, precise finishes and minimal overspray

- Industrial Equipment: Finishing machinery, tools, and metal parts with durable, consistent coatings

- Electronics and Appliances: Applying protective and decorative coatings on delicate surfaces where precision is crucial

By providing controlled, uniform coating, HVLP spray guns enhance productivity while maintaining high-quality standards across diverse production environments.

Conclusion: Maximizing Efficiency and Quality with HVLP Automatic Spray Guns

HVLP automatic spray guns leverage high-volume, low-pressure technology to deliver precise, uniform, and efficient coatings across a wide range of applications. From automotive and aerospace components to furniture, industrial equipment, and electronics, these spray guns reduce overspray, minimize material waste, and enhance surface quality, with HVLP paint sprayers providing additional versatility for specialized coating tasks.

By combining improved transfer efficiency, superior finish consistency, and seamless integration into automated production lines, HVLP paint guns provide both economic and environmental benefits. For manufacturers seeking reliable, high-quality, and cost-effective coating solutions, HVLP automatic spray guns remain an indispensable tool in modern industrial spraying applications.