How Automatic Spray Guns Reduce VOC Emissions in Modern Manufacturing?

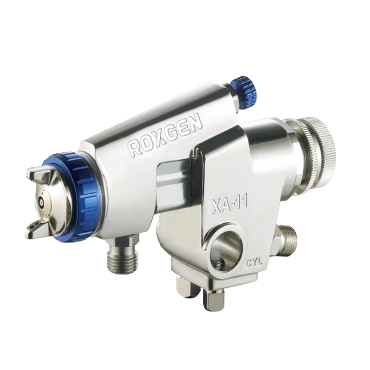

At RANOX ENTERPRISE INC., we recognize the growing demand for sustainable coating solutions across industries. Automatic spray guns and automatic paint guns are no longer just about improving efficiency and coating quality—they are critical tools in reducing volatile organic compound (VOC) emissions. VOCs, commonly found in paints and solvents, are a major concern for environmental safety and worker health. By adopting advanced automatic spray systems, manufacturers can lower VOC output, save material costs, and comply with increasingly strict global environmental regulations.

Why VOC Reduction Matters

Volatile Organic Compounds (VOCs) are a leading cause of air pollution and pose health risks when released in large quantities. Traditional manual spraying methods often result in high material waste and uncontrolled overspray, which contribute directly to VOC emissions. In contrast, automatic spray guns offer precision, consistency, and integration with enclosed systems, making them a sustainable choice for modern industrial operations.

Key Contributions of Automatic Spray Guns to VOC Reduction

1. Higher Transfer Efficiency

Automatic spray guns are engineered to maximize the percentage of paint that adheres to the target surface.

- Manual spraying transfer efficiency: 30%–50%

- Automatic spray systems (e.g., HVLP and electrostatic): 65%–90%+

This improvement translates into less overspray, reduced paint waste, and fewer VOCs released into the atmosphere.

| Spray Method | Typical Transfer Efficiency | VOC Impact |

|---|---|---|

| Manual Spray Guns | 30%–50% | High emissions due to overspray |

| HVLP Spray Guns | 65%–75% | Significant reduction |

| Electrostatic Spray Guns | 80%–90%+ | Lowest VOC emissions, highly efficient |

2. Consistent and Uniform Application

With pre-programmed settings, automatic paint guns deliver coatings with precision. This reduces human error, prevents uneven coverage, and minimizes the need for rework. Less rework means fewer additional paint layers, ultimately lowering VOC emissions.

3. Integration with Enclosed and Automated Systems

Automatic spray guns are often combined with robotic arms, conveyor-based systems, and enclosed spray booths. These setups:

- Capture excess paint particles and VOC vapors.

- Improve workplace safety and environmental compliance.

- Support continuous, automated production with reduced emissions.

4. Reduced Paint Consumption through Precision Control

Because automatic spray systems optimize droplet size, spray angle, and flow rate, they require less paint for the same coverage area. Since VOC emissions are directly proportional to solvent-based paint usage, this efficiency directly contributes to emission reduction.

5. Compatibility with Low-VOC and Water-Based Coatings

Modern automatic spray technology is designed to handle low-VOC formulations and water-based paints. When combined with efficient spray systems, these coatings further reduce emissions while maintaining durability and surface finish quality.

Regulatory Compliance: EU and U.S. Standards

EU VOC Directive

The European Union VOC Directive (Directive 2004/42/EC) regulates the amount of VOCs in paints, varnishes, and vehicle refinishing products. It requires manufacturers to limit VOC content and adopt cleaner technologies to minimize emissions across industrial and commercial applications. This directive pushes industries toward automatic spray systems that improve efficiency and comply with legal emission limits.

- Reference: EU VOC Directive Overview

U.S. EPA Standards

In the United States, the Environmental Protection Agency (EPA) regulates VOC emissions under the Clean Air Act. The EPA sets limits for industrial coating operations, mandating emission reduction strategies that often include the use of high-efficiency automatic paint guns, closed spray booths, and low-VOC coatings. Compliance is critical not only for environmental responsibility but also to avoid fines and production disruptions.

- Reference: U.S. EPA VOC Regulations

Together, these regulations highlight the importance of adopting advanced automatic spray systems to meet both environmental standards and customer expectations for sustainable production.

Industry Trends: Sustainability and Regulations

Across industries such as automotive, aerospace, heavy machinery, and consumer goods manufacturing, companies are shifting toward green coating technologies. Governments and regulatory bodies worldwide are enforcing stricter VOC limits, accelerating the adoption of automatic spray systems.

- Automotive sector: Moving toward waterborne paints and automated finishing lines.

- Aerospace manufacturing: Demanding uniform coatings with minimal emissions.

- Heavy machinery and equipment: Emphasizing cost savings from reduced material usage.

- Global regulations: EU VOC Directive and U.S. EPA Standards are driving innovation in spray technology.

Automatic spray guns are therefore not only a productivity tool but also a compliance solution for long-term sustainability.

Conclusion

At RANOX ENTERPRISE INC., we see automatic spray paint guns as essential solutions for modern manufacturers striving to balance efficiency, quality, and sustainability. By improving transfer efficiency, minimizing waste, and supporting environmentally friendly coatings, automatic spray systems directly reduce VOC emissions while ensuring compliance with global environmental regulations.

If your business is looking to upgrade its coating technology for better performance and compliance, we invite you to connect with us.

Contact RANOX ENTERPRISE INC. today to explore our full range of automatic spray guns and industrial coating solutions.