How Automatic Spray Guns for Automotive and Cars Improve Finish Quality and Consistency

In modern automotive manufacturing and refinishing, automatic spray guns for automotive and cars are essential technologies that dramatically improve surface finish quality, reliability, and production efficiency. Compared with traditional manual spraying, automatic spraying systems reduce variability and ensure every vehicle, including sedan, SUV, and commercial auto coatings, meets industry standards for appearance and durability.

Why Automatic Spray Guns Matter in Automotive Painting

Automotive paint quality directly impacts a vehicle’s visual appeal, corrosion resistance, and long-term performance. Automatic spray guns, often integrated into robotics and factory automation systems, deliver consistent, high-precision finishes in ways manual methods cannot. Below are the core advantages:

Improved Consistency and Precision

Automatic spray systems program spray patterns, pressure, distance, and angle for every surface, ensuring uniform coating thickness across every part of the body shell and complex contours. This reduces issues such as:

- Color variations between panels

- Uneven film thickness

- Paint runs or sagging

Such programmatic control is critical in meeting OEM and Tier-1 quality standards.

Enhanced Atomization and Surface Quality

Advanced automatic spray guns produce ultra-fine atomization, generating microscopic paint particles that adhere more consistently to metal and composite surfaces. The result is:

- Smoother finishes with higher gloss

- Better adhesion for top-coat and clear-coat systems

Longer resistance to corrosion, UV, and weathering

Alignment with Industry Trends in Automotive Manufacturing

The adoption of automatic spray guns for automotive and cars aligns with broader industry shifts toward automation, sustainability, and data-driven production.

Market Growth & Technological Trends

According to recent industry analysis, the global automotive automatic spray guns market is expanding rapidly due to:

- Increasing vehicle output (over 80 million units globally)

- Demand for precise coatings on water-based and low-VOC paints

- Integration of IoT sensors and real-time monitoring on spray systems

- Robotic painting cells capable of 24/7 operation and repeatable quality

Automatic spray guns now represent a majority share of industrial coating systems in automotive production lines.

Sustainability & Compliance

Environmental regulations worldwide are encouraging:

- Adoption of low-VOC coating processes

- Reduction of overspray and material waste

- More efficient paint transfer rates up to ~90% (vs. <40% in manual systems)

These improvements support compliance with standards in North America and Europe, and reflect growing factory sustainability goals.

Key Benefits of Automatic Spray Guns vs. Manual Methods

Below is a comparison of automatic spray guns for automotive and cars versus traditional manual spray approaches:

| Feature | Manual Spray Guns | Automatic Spray Guns |

| Coating Consistency | Variable (operator-dependent) | High (programmed precision) |

| Material Efficiency | ~30–40% transfer | Up to ~90% transfer |

| Waste & Overspray | High | Significantly reduced |

| Labor Requirements | High | Reduced (robots/automation) |

| VOC Exposure | High | Lower (enclosed systems) |

| Repeatability | Limited | High, ideal for mass production |

| Integration | Stand-alone | Factory automation & IoT monitoring |

This table highlights how automatic spray systems optimize both quality and operational cost for automotive OEMs and refinish facilities.

Practical Applications on Production Lines

Automatic spray guns find use across automotive paint operations, including:

- Full vehicle body painting on assembly lines

- Rust-proof and primer application on chassis

- Partial repair and refinishing operations

- Custom finish and multi-layer applications

When paired with multi-axis robotic arms, automatic spray systems can navigate complex shapes and tight spaces, achieving uniform coverage and reducing defects.

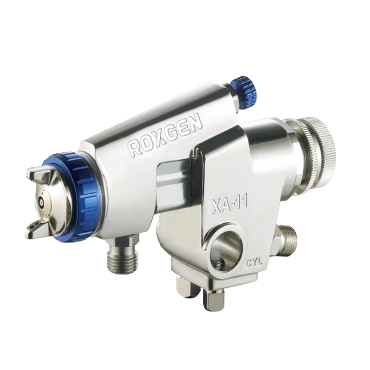

Choosing the Right Automatic Spray Solution

For manufacturers, body shops, and automotive refinishers deciding on an automatic spray gun system, consider:

- Transfer efficiency & atomization technology

- Integration with robotics/automation

- Compatibility with eco-friendly coatings

- Real-time quality monitoring via IoT

These factors influence ROI, operational uptime, and finish quality, especially in high-volume automotive production environments.

Conclusion

In the automotive industry, automatic spray guns for automotive and cars are no longer optional, they are vital for achieving consistent, high-quality finishes while increasing production efficiency and lowering waste. Their integration with automation, robotics, and digital monitoring aligns with trends in smart factories and sustainability.

If you are looking for advanced automated automotive painting solutions, please contact RANOX ENTERPRISE now!